Condition:

New

Type:

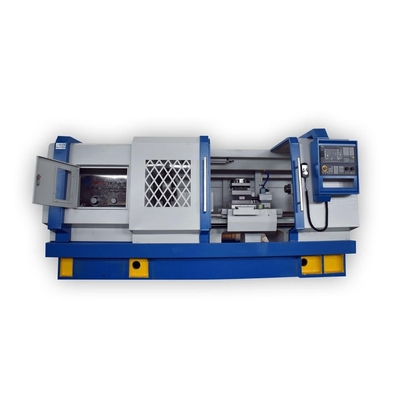

Horizontal

Year:

2020

Max. Length of Workpiece (mm):

3000 mm

Structure:

Flat Bed Lathe

Max. Spindle Speed (r.p.m):

450 r.p.m

Machining Capacity:

Light Duty

Spindle Bore(mm):

105 m'm

Width of bed (mm):

660 mm

Spindle Motor Power(kW):

11

No. of Spindles:

Single

Number of Axes:

2

Travel (X Axis)(mm):

630 mm

Travel (Z Axis)(mm):

3000 mm

Positioning Accuracy (mm):

0.01

Repeatability (X/Y/Z) (mm):

0.007

Dimension(L*W*H):

2150*1300*1700mm

Model Number:

1319

Voltage:

220V/380V

CNC Control System:

GSK

Toolpost Brand:

Hongda

Tool Post Stations:

4

Weight (KG):

4500

Warranty:

1 Year

Applicable Industries:

Machinery Repair Shops, Manufacturing Plant, Retail, Construction works , Energy & Mining

Key Selling Points:

Competitive Price

Showroom Location:

United States, Italy, Indonesia, India, Mexico, Thailand, Argentina

Guide way width:

550mm

Max swing over bed:

630mm

Max swing over slide:

350mm

Max working piece length:

1500/3000

Tool post style:

vertical 4 station

Motor power:

11KW

Controller:

KND/FANUC/SIEMENS

Machining accuracy:

IT7

Workpiece surface roughness:

Ra1.6

Bed quenching hardness:

HRC52

After-sales Service Provided:

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

After Warranty Service:

Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, South Korea, Chile, UA

Max. Swing Diameter (mm):

630 mm

Certification:

CE ISO9001

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!